In the era of sustainability, efficient management of urban sanitation and water supply network projects has become essential. In this context, the implementation of the BIM (Building Information Modeling) methodology emerges as a fundamental pillar in this process.

As we have explained in previous posts, BIM modeling is a powerful tool to effectively support installation projects while managing and coordinating the design. BIM ensures productivity, saving time and money, virtually resolving conflicts, and representing the design intent with a high level of detail.

According to the Public BIM Tender Observatory, the use of BIM methodology is a requirement in more than 70% of public tenders in Spain for the construction of new buildings. So in this case, it is important to know how it intervenes in the management and planning processes of piping systems.

What does the BIM methodology involve?

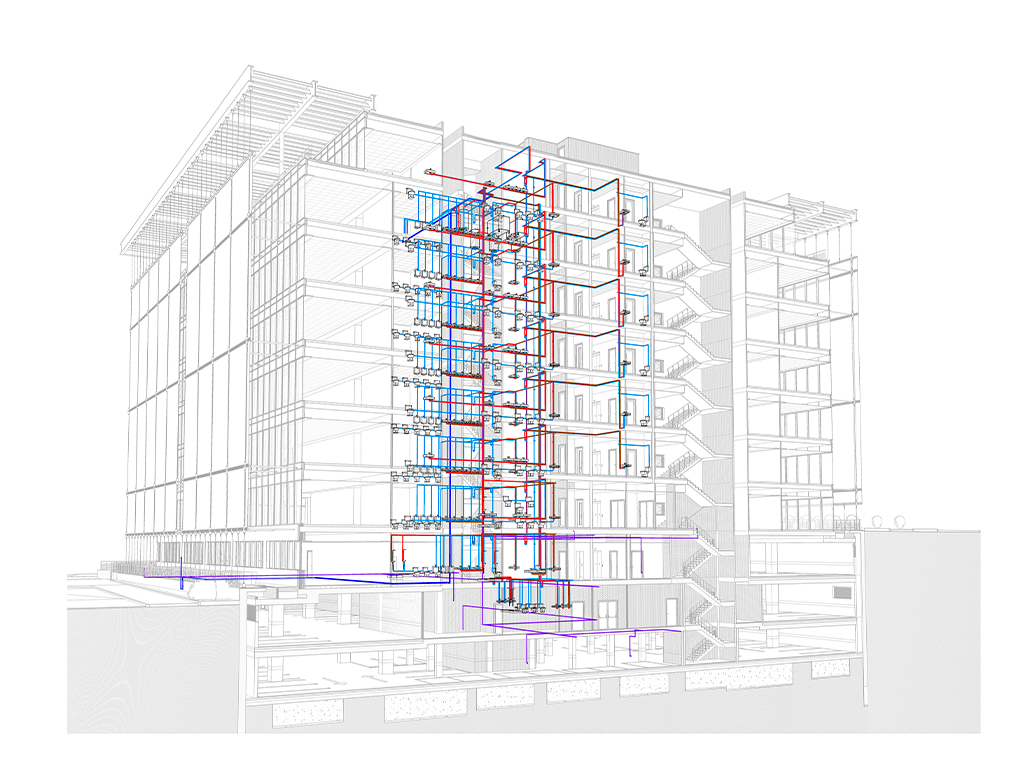

Thanks to its ability to create detailed and up-to-date three-dimensional models, BIM facilitates the planning and coordination of pipe system installations, optimizing performance and efficiency.

Under the premise of enabling real-time collaboration through the exchange of digital information, it allows engineers, architects, and construction companies to collaborate effectively without the need for physical proximity.

In addition, it guarantees early detection of conflicts and the generation of complete documentation ensuring smooth implementation, reducing costs and associated risks.

So BIM not only transforms the way these projects are conceived and executed, but also contributes significantly to the sustainability and reliability of pipeline system infrastructures.

Applications of the BIM Methodology

In essence, BIM disrupts traditional design and construction by offering a precise virtual representation of pipe system components to scale. This approach offers several uses that facilitate both coordination and project execution.

First of all, it allows for a detailed three-dimensional visualization of the entire system, facilitating the identification of potential interferences with other construction elements, such as pipe systems, structures, electrical conduits, or fire protection systems. Additionally, BIM enables precise planning of the installation sequence, allowing teams to anticipate potential logistical or space-related challenges.

This methodology provides information about pipe dimensions and characteristics, as well as the necessary connections and accessories. This means that more accurate material orders can be made, reducing waste and associated costs.

In addition, real-time information available in the BIM model allows for continuous monitoring of installation progress, facilitating early detection of issues and informed decision-making for their correction.

Advantages of the BIM Methodology for Pipe Installation

Implementing such methodologies in any installation project represents a radical change compared to traditional methods and provides several advantages for installers or property owners who oversee execution.

- Improved coordination and collaboration among teams: This methodology allows all involved professionals to access a centralized and updated model, reducing errors and conflicts during pipe installation.

- Prevention of structural problems: BIM enables the early detection of obstructions and conflicts between different design elements.

- Optimization of design work: Professionals can perform simulations and analyses to optimize pipe system designs. Including the selection of pipe sizes and routes to enhance performance and efficiency.

- Precise planning and scheduling:: The system provides tools for detailed planning and scheduling of pipe installation.

- Precise planning and scheduling:: With a detailed three-dimensional model, accurate budget estimates can be made.

- Provision of precise and updated information: This includes plans, material lists, and specifications.

- Assistance in manufacturing and prefabrication: This methodology allows for the creation of specific models for pipe component manufacturing, facilitating prefabrication in workshops and potentially accelerating on-site installation.

- Asset management and maintenance tool: After construction, the BIM model serves as a tool for asset management and maintenance throughout the building’s lifecycle.

- Regulatory compliance: Thanks to its constant updates, this methodology can help ensure compliance with local regulations and standards regarding pipe system installations.

- Contributes to waste reduction and safety risk reduction: By enabling more precise and detailed planning, BIM can reduce material waste during pipe installation. Additionally, by identifying and addressing conflicts before construction, the risk of accidents and injuries at the workplace is reduced.

Successful Cases of BIM Methodology Application

The implementation of the BIM methodology stands out as a significant milestone for the sustainable construction industry, as demonstrated by successful projects such as the Cajamar headquarters and the Bouaké stadium.

Cajamar Headquarters:

Located in the Almería Technology Park (Pita), the Cajamar headquarters. This building is designed to develop business activity in the most efficient way possible, facilitating joint management and a commitment to quality, comfort, sustainability and energy savings.

Its unique structure changes alignment from below to above ground, transitioning from a rectangular shape on the lower three floors to a six-arm design above the surface Its unique structure changes alignment from below to above ground, transitioning from a rectangular shape on the lower three floors to a six-arm design above the surface

In terms of the construction process, advanced tools and technologies were used for planning and control, crucial for a project of this magnitude. Collaborative BIM was employed to coordinate the efforts of all stakeholders.

Bouaké Stadium:

The project, which was entirely developed in an integrated and coordinated BIM environment, involves the renovation and expansion of the football stadium in Bouaké, Ivory Coast, for the 2023 African Cup of Nations.

The stadium’s structural solution includes reinforced concrete portal systems and a cantilevered metal roof of approximately 25 meters. In this case, the pipe systems consist of a collection of hydraulic conduits made of halogen-free polypropylene with oxygen barriers.

Additionally, architectural, engineering, and infrastructure projects were undertaken for a 32-villa condominium, as well as renovation projects for 12 training fields and a currency exchange house.