Preguntas frecuentes acerca de sistemas de tuberías

CONCEPTOS BASICOS PARA REDES DE PRESIÓN

Serie (S) = (dn – e)/(2*e)

dn es el diámetro nominal, exterior, de la tubería. e es el espesor nominal de la pared de la tubería.

SDR = dn/e

dn es el diámetro nominal, exterior, de la tubería. e es el espesor nominal de la pared de la tubería

- Clase 1: tuberías para el suministro de agua caliente sanitaria a 60 ºC.

- Clase 2: tuberías para el suministro de agua caliente sanitaria a 70 ºC.

- Clase 4: calefacción por suelo radiante y radiadores a baja temperatura.

- Clase 5: tuberías para calefacción por radiadores a alta temperatura.

Las presiones de funcionamiento cambian según la materia prima que se utilice. A igualdad de espesor de pared, las de PP R son inferiores a las de PP RCT y estas inferiores a las de PP RCT RP.

Hay que tener en cuenta que también influye la serie (espesor del tubo para comparar estas presiones)

Presiones admisibles para:

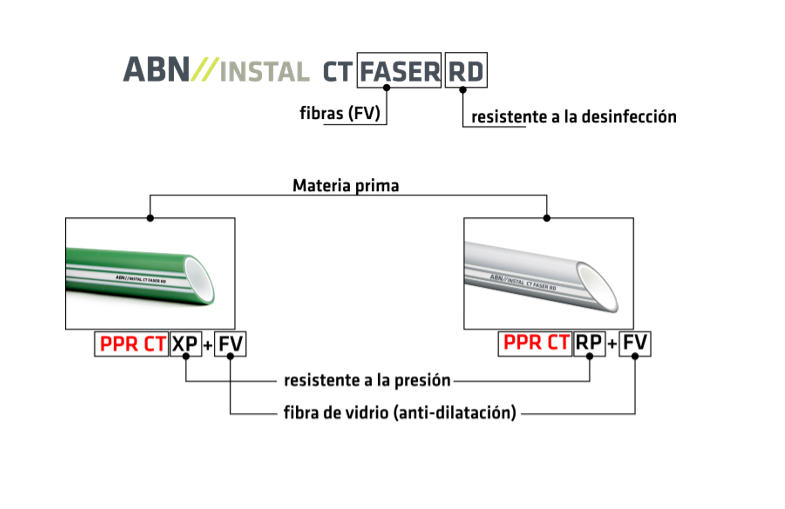

ABN//INSTAL CT FASER RD

ABN//INSTAL CT FASER RD FIRE

|

Presiones en bar a 50 años de funcionamiento |

||||

|

SERIE |

20 ºC |

60 ºC |

70 ºC |

** 80 ºC |

|

3,2 |

31,7 |

17,7 |

14,9 |

12,7 |

|

5 |

20,3 |

11,3 |

9,5 |

8,1 |

|

8 |

12,6 |

7,1 |

5,93 |

5,1 |

Presiones admisibles para:

ABN//INSTAL CT FLEX RD

|

Presiones en bar a 50 años de funcionamiento |

||||

|

SERIE |

20 ºC |

60 ºC |

70 ºC |

** 80 ºC |

|

3,2 |

20,3 |

11,3 |

9,5 |

8,1 |

|

– Polipropileno-homopolímero PP-H (también conocido como tipo 1) |

PP-H comprende todos los homopolímeros de polipropileno; |

|

– Polipropileno-copolímero de bloque PP-B (también conocido como tipo 2) |

PP-B comprende copolímeros termoplástico de propileno en bloque, que no contengan más del 50% de otro(s) monómero(s) olefínico(s), ni de otro grupo funcional distinto del grupo olefínico, copolimeralizado con propileno; |

|

– Polipropileno-copolímero al azar PP-R (también conocido como tipo 3) |

PP-R comprende copolímeros termoplásticos de propileno al azar que no contengan más del 50% de otro(s) monómero(s) olefínico(s), ni de otro grupo funcional distinto del grupo olefínico, copolimeralizado con propileno; |

|

– Polipropileno-copolímero al azar con cristalinidad modificada PP-RCT (también conocido como tipo 4) |

PP-RCT comprende copolímeros termoplásticos de propileno al azar que no contengan más del 50% de otro(s) monómero(s) olefínico(s), ni de otro grupo funcional distinto del grupo olefínico, copolimeralizado con propileno. |

EVACUACIÓN

Áreas de aplicación

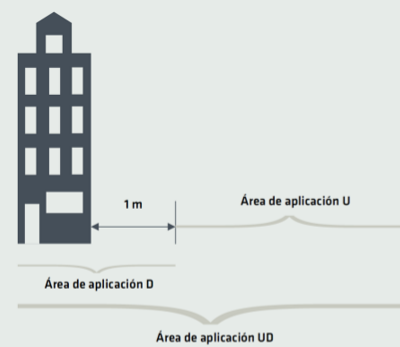

No se deben instalar tubos y accesorios de SN 2 en áreas donde se produzcan descargas de agua caliente. La normas de saneamiento sin presión definen dos series o áreas de aplicación:

U – Código de área de aplicación en el exterior de la estructura deledificio, hasta 1 m del mismo, en la cual es conectado el sistema de tuberías de saneamiento.

D – Código de área de aplicación enterrado, tanto en el interior de laestructura del edificio como en el exterior del edificio, a partir de 1 m del mismo en donde los tubos y accesorios son conectados al sistema de descarga del edificio.

Estas normas también indican la clasificación de tubos y accesorios que pueden ser usados en cada área de aplicación.

Nota: Las clases de tubos SN 4 y SN 8 son adecuadas para ambas aplicaciones, por lo que pueden ser marcadas UD.

|

|

PRESIÓN POSITIVA |

PRESIÓN NEGATIVA (DEPRESIÓN) |

|

ABN//EVAC ENERGY PLUS |

+ 1 bar |

-0,9 bar |

|

ABN//EVAC HT PHONO |

+ 1 bar |

En ensayo |

DECIBELIOS

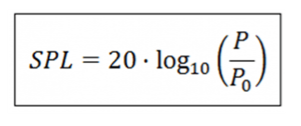

El decibelio (dB) es una unidad relativa, que sirve para expresar la relación entre la magnitud de interés respecto a un valor de referencia. No representa por sí mismo un valor dentro de una escala absoluta: hay que indicar cuál es la referencia.

Del mismo modo que no oímos decibelios, sino oscilaciones de presión sonora (vibraciones de las partículas del aire).

El decibelio NO es una unidad de medida de sonido

P: presión eficaz (Pa)

P0: presión de referencia = 20·10-6 Pa

Y de cómo representa mejor cómo se sienten realmente en el oído del ser humano los cambios en la intensidad del sonido.

Imaginemos un edificio de 80 metros de altura. Si ampliásemos su altura en 10 metros más (90m en total), a la vista parecería sólo un poco más alto porque en realidad hemos incrementado su altura en un 12,5%.

Si trasladamos estas magnitudes a dBA, si un sonido tiene 80 dBA de intensidad, al añadirle 10 dBA adicionales, el sonido sería 10 veces más intenso; aproximadamente el doble de fuerte para nuestros oídos.

Dependerá de dónde estemos frente a la fuente del sonido.

Los dBA son una unidad de presión acústica, una medida de fuerza y más concretamente una medida de fuerza por unidad de área.

Cada vez que nos alejamos de la fuente de sonido, éste pierde intensidad en una relación de 6 dB cada vez que la distancia se duplica.

Ejemplo: Si a un metro percibimos 80 dB, a dos metros percibiremos 74 dB, a cuatro metros 68 dB

y a ocho metros, 62 dB).

Por lo que importante y fundamental que a la hora de medir la intensidad de presión acústica se indique la distancia a la que se mide, y ahí es donde entran en juego los dBA.